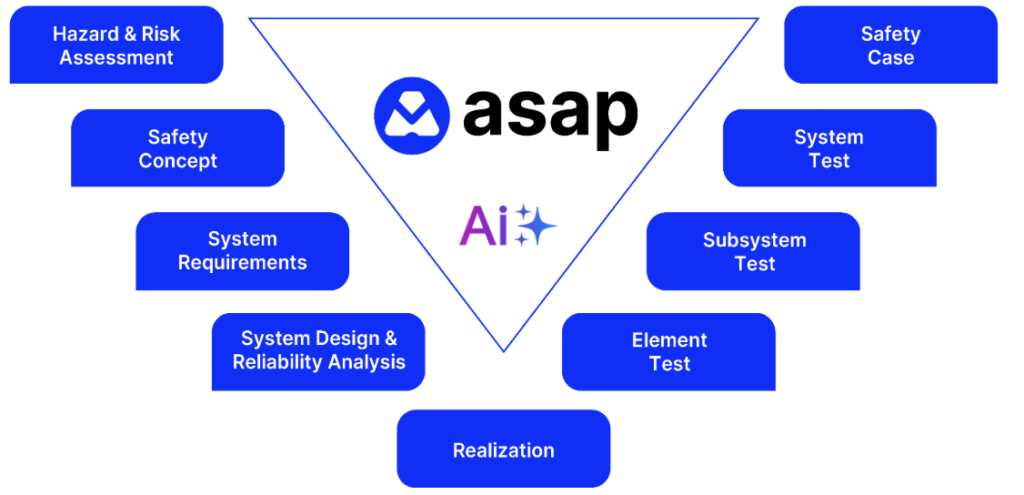

Functional safety development, as guided by standards like IEC 61508, ISO 13849 or ISO 26262, relies on a structured lifecycle approach to ensure that safety is designed into a system from its inception.

Functional safety certification does not happen on accident. It requires a deliberate and structured approach, which is precisely what the functional safety lifecycle provides. Adhering to these defined phases is crucial because it ensures a systematic and comprehensive consideration of all safety aspects.

The lifecycle phases act as a roadmap, guiding developers through the necessary steps to identify potential hazards, define appropriate safety requirements, implement effective safeguards, and verify that the system behaves as intended under both normal and fault conditions.

Ultimately, following the lifecycle is not just a best practice, but a fundamental requirement for achieving and demonstrating functional safety.

Although it sounds like an easy process to follow, the real world proves it can be very difficult to adhere to. Between design changes, supply chain problems, and ever-changing product requirements, following the structured lifecycle approach linearly is never as easy as it seems.

If you are still doing your safety development in spreadsheets, you know that trying to manage the interconnection of lifecycle phases is a nightmare. Relying on macros-based-spreadsheets to track down entities from various sheets to develop a complex system leaves you and your safety assessor questioning the reliability of your process.

This may leave you in the middle of your functional safety development process trying to answer questions like:

- Can I introduce my system into a new environment or use-case?

- What if I need to change a system requirement?

- What if I am changing an assumption I made when I first started my process?

- Can I re-use a Safety Function on a different system?

- What test cases do I need to re-run if I change my hardware?

- Am I still compliant if I change my system design?

With ASAP’s unique attribution model, all lifecycle phases are interconnected.

Throughout your entire safety development lifecycle, users are able to understand exactly how entities are connected to downstream and upstream lifecycle phases. Programs across industries are reaping the benefits of ASAP’s unifying attribution across lifecycle, such as:

- Automated Inputs and Outputs: ASAP allows you to automate the outputs of one lifecycle phase and the inputs of the next. No more trying to manage entities across spreadsheets.

- Ensuring Requirements Coverage: Traceability ensures that all safety requirements defined in the initial phases are properly addressed in the subsequent design, implementation, and testing phases.

- Supporting Impact Analysis: Change is one of the few things that is constant in system development. With ASAP, it is simple to identify which parts of the system need to be re-evaluated or re-tested after a change.

- Facilitating Verification and Validation: By ASAP’s connection of requirements to design elements and test cases, traceability enables efficient verification and validation.

- Building Trust with Safety Assessors: During safety audits and assessments, traceability through ASAP demonstrates a systematic and rigorous approach to safety engineering.

Automated traceability acts as a backbone for the entire safety lifecycle, ensuring that safety is considered at every stage and that the final system meets its intended safety goals. ASAP’s unifying attribution gives everyone the confidence to guarantee traceability at all stages of development.