Faster launches shouldn’t mean taking shortcuts.

Schedule a consultation to see how ASAP helps you build safer systems in less time, with full certification support built in.

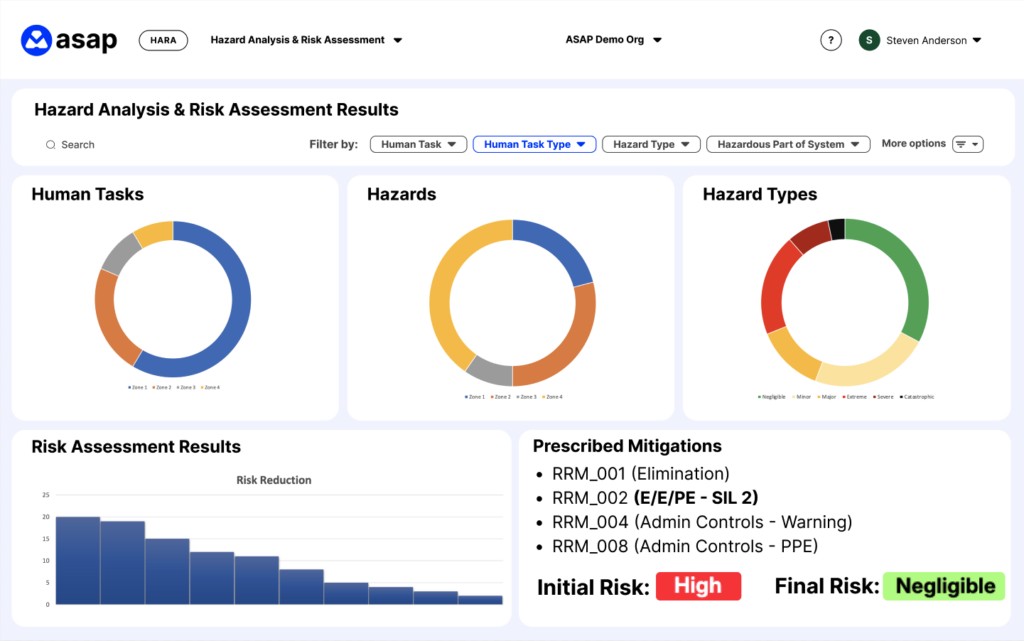

ASAP is a full-lifecycle platform that helps engineering teams build safer systems faster. It guides you through a structured, standards-based process for certifying complex products with confidence.

Safety work is often spread across disconnected tools.

Engineers lose time copying data, tracking changes, and coordinating documentation instead of focusing on what matters—building safe systems.

Without a unified process, safety documentation is inconsistent, redundant, and hard to verify.

Teams waste hours stitching together documents that don’t align or support certification.

Manual reporting slows everything down.

Whether you’re preparing a safety case or coordinating with assessors, fragmented tools create bottlenecks that delay progress and increase risk.

ASAP is used by engineering teams across robotics, manufacturing, and operations to standardize safety work. It simplifies certification and ensures your process meets industry standards with traceability built in from the start.

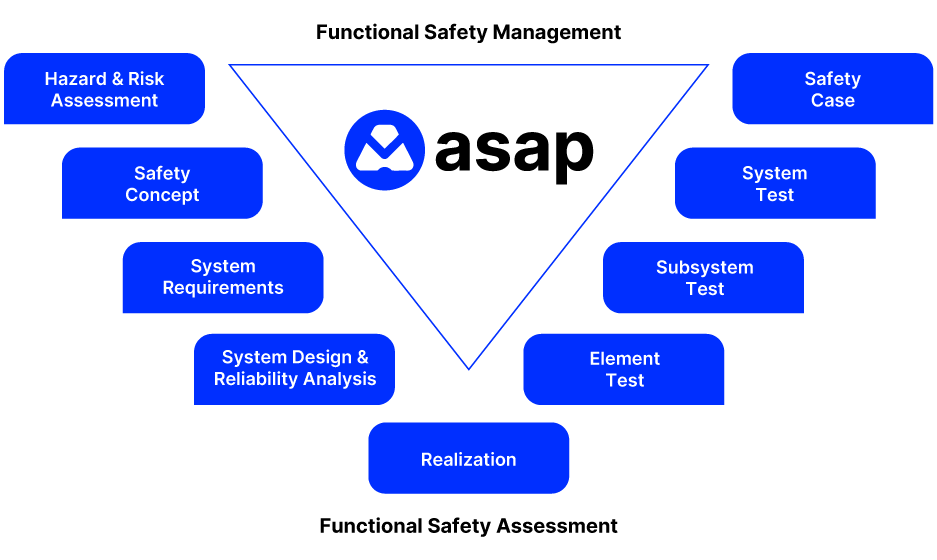

ASAP is a safety lifecycle platform that guides teams through every phase—from hazard analysis and requirements to validation and monitoring.

It’s built around the industry-standard V-model and supports certification with traceable, assessor-ready documentation.

ASAP replaces spreadsheets and disconnected tools with a structured, automated system.

It simplifies change management, supports team collaboration, and helps you stay compliant—without slowing down development.

Built to the prescriptive V-Model defined in IEC 61508, ISO 13849, and ISO 26262, ASAP enables you to build your system using the safety lifecycle model that assessors are familiar with. As it complies with these core standards, ASAP is also influenced heavily by other functional safety standards, including:

ASAP has earned its T2 qualification through TÜV Rheinland. That qualification validates the consistency and reliability of the platform and makes it eligible for assessor-qualified use.

ASAP makes advanced safety work accessible to teams of all sizes.

It embeds structure, guidance, and automation into every step—so even lean teams can meet the same standards as enterprise leaders.

ASAP automatically generates traceable, assessor-ready outputs.

Teams spend less time formatting files and more time building. Every safety case is audit-ready from day one.

ASAP connects your safety workflow to real system data.

It automatically updates safety cases when inputs or specs change—reducing rework and improving accuracy across the board.

ASAP brings structure to complex safety work.

It’s a system you can trust to walk your team from early risk analysis to certification, no matter your experience level.

Faster launches shouldn’t mean taking shortcuts.

Schedule a consultation to see how ASAP helps you build safer systems in less time, with full certification support built in.

Get ASAP Now

Fill out the form below, and a Fennec Engineering team member will get back to you to schedule a consultation.