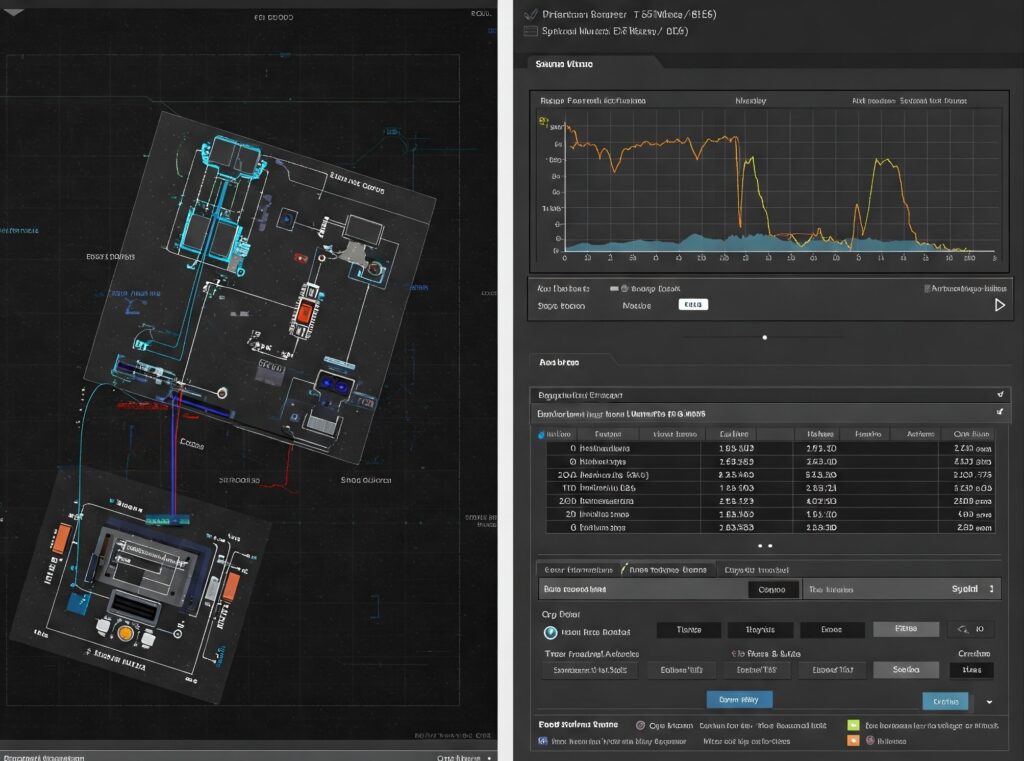

Developing complex embedded systems, especially those involving AI or safety-critical components, demands rigorous testing. ASAP simplifies this process by offering both Hardware-in-the-Loop (HiL) and Software-in-the-Loop (SiL) testing capabilities within a unified platform. It tackles the often tedious task of setting up and managing complex software toolchains, providing direct integrations with a wide range of test facilities.

Whether you’re working with virtual environments, physical test tracks, robotic automation cells, or even manufacturing areas, ASAP can orchestrate the necessary connections. This includes managing resources like GPUs and spinning up custom toolchain setups tailored to different operating systems and toolsets, significantly reducing the overhead typically associated with these processes.

The real power of ASAP lies in its ability to connect these diverse testing environments and the resulting reports, enabling automated integration and attribution across the entire product lifecycle. For example, you can use ASAP to test AI models for consistency and verifiability throughout their development, deployment, and maintenance. Similarly, it facilitates HiL and SiL testing of drive unit controllers and firmware, allowing you to examine various test artifacts and metrics. Critically, ASAP links these test results to essential safety lifecycle capabilities, such as hazard and risk assessments, safety concepts, and reliability analyses. This integrated approach ensures traceability and simplifies compliance by providing a single source of truth for all testing and safety-related documentation. Traceability is a critical component of safety certification, as it allows regulators and auditors to easily follow the chain of custody for all safety-related documentation and testing. This ensures that all aspects of the product’s development and testing have been properly documented and can be traced back to the original source.